Controlling Noise Hazards Within Your Facility

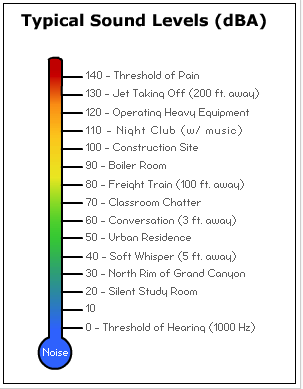

One of the occupational hazards that some people may overlook is the impact sustained noise exposure can have on you or your employees. In fact, "22 million workers are exposed to potentially damaging noise at work each year," according to CDC estimates. When we think of loud jobs, construction work, or heavy manufacturing environments probably come to mind, and these are exceptionally noisy environments. However, noise hazards can occur at decibel levels as low as 85 dB with sustained exposure. That is roughly as loud as your average city street during rush hour. [1] This sound level would not necessarily register as harmful when heard, but noises at or above 85 dB can cause hearing loss over time by killing nerve endings within our inner ear.

Luckily, The National Institute for Occupational Safety and Health (NIOSH) and CDC offer a variety of tools and tricks to help employers and employees reduce the effects of Occupation Noise Exposure. This post will discuss how facilities can address noise hazards and how Panel Built, Inc. can help make a difference!

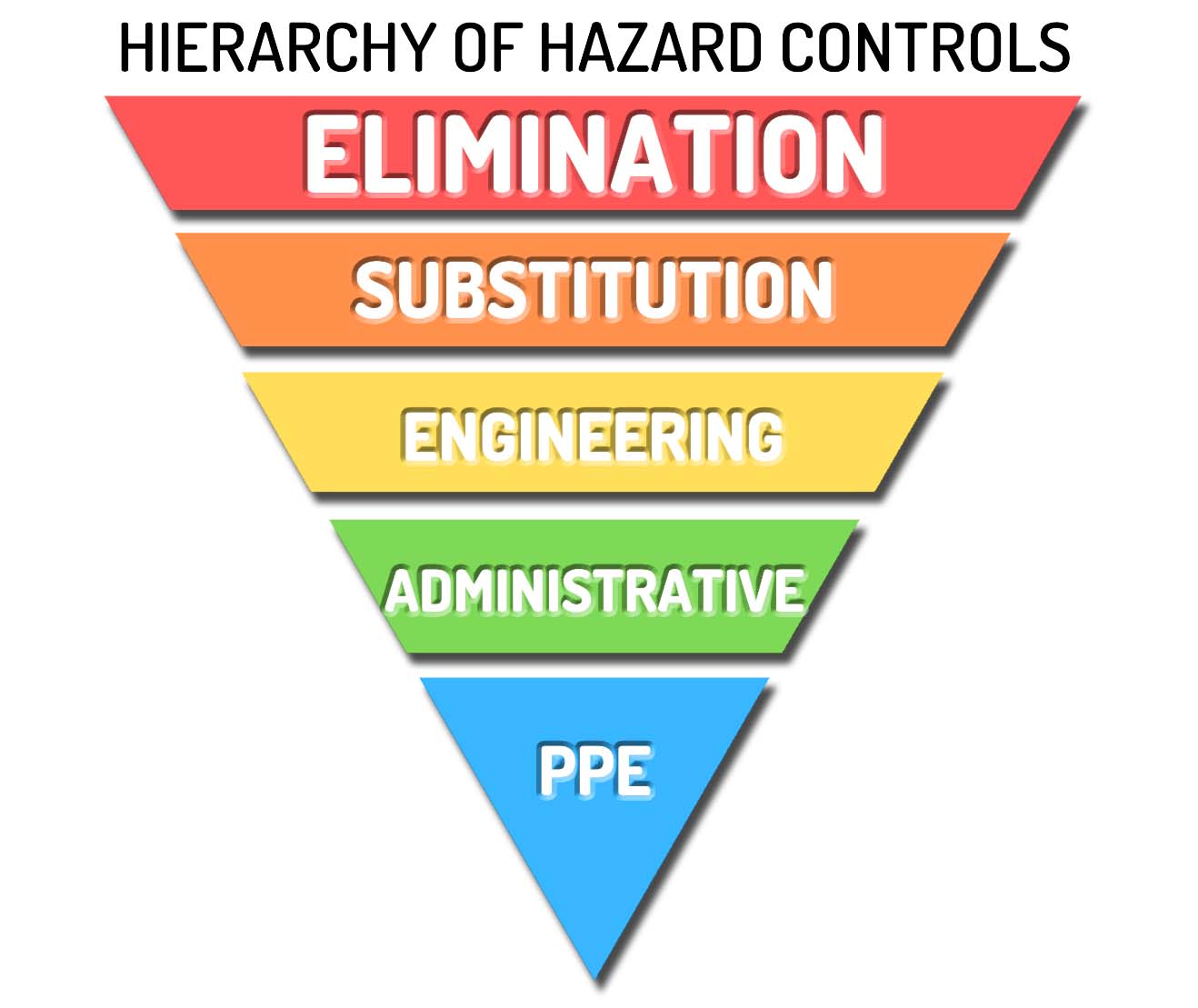

The Hierarchy of Hazard Control

As we have mentioned before in our blog, The Hierarchy of Hazard Control is the most effective way to mitigate a hazard in your facility, whether noise-related or not. Therefore, when using the Hierarchy, always use the highest level possible to manage your risk as the system is arranged from most to least effective.

Eliminating The Noise Hazard

At the top of the Hierarchy of Controls is Elimination. As you can imagine, the best and most practical way to reduce a threat is to get rid of it entirely from your facility--simple enough. However, if eliminating hazards from a facility was that easy, businesses would not have to worry much about them. Unfortunately, many risks present in a facility are inherent to the production process.

Factory noise will be present in practically any facility as a by-product of manufacturing. For example, almost all moving parts would have to be removed to eliminate noise from a sawmill, like the saws, conveyors, trucks, etc. This sawmill would not be able to produce a lot of lumber. Therefore, they would have to move further down the Hierarchy of Controls to control their noise hazards.

Substituting The Noise Hazard

The next rung down our Hierarchy tells us to look for an alternative solution. As the second option, substitution is still a highly effective avenue to mitigate hazard risks. In the case of controlling noise hazards, NIOSH has developed an initiative to help companies and organizations substitute their loud equipment. The Buy Quiet initiative encourages companies to "purchase or rent quieter machinery and tools to reduce worker noise exposure."

The program aims to generate more, quieter alternatives to practically any high noise level pieces of equipment. The government program drives companies to evaluate and search out less noisy equipment to promote the hearing health of their employees and reduce noise-related worker compensation claims. A subsequent result of this is positive pressure on equipment manufacturers to create overall less noisy equipment. The Buy Quiet initiative is successful for new companies designing a facility or existing plants to reduce current noise levels.

Controlling Noise Hazards With Engineering Controls

After the first two steps, many facilities may still find themselves with an average noise level above the regulated 85 dBs. However, the engineering controls portion of the Hierarchy offers solutions for manufacturing and industrial facilities of nearly all types. When mitigating sounds, engineering controls recommend placing some sort of barrier between the noise source and employees. In fact, at Panel Built, we have an entire line of products dedicated to helping facilities introduce new engineering controls within their facilities.

Panel Built sound-dampening wall systems and equipment enclosures are a fully customizable engineering solution to help reduce the decibels emanating through your facility.

The NIOSH's "Solutions for Reducing Noise in the Workplace" lists six solutions to reduce hearing loss prevention [2]. Half of these recommend installing some type of barrier between the noise source and employees. Panel Built's modular wall systems can help you accomplish each of these.

The noise source can be isolated via an insulated enclosure. Panel Built modular walls allow for fully custom layouts and designs, perfect for fitting around unique pieces of machinery. This creates a physical barrier between your employees and the hazard. Panel Built's sound rated panels implement specialized sound absorbing boards to minimize sound transmission.

On the other hand, sound dampening rooms can be formed through the system to create a comfortable workspace for your employees. Heavy manufacturing environments utilize these panels to create more relaxed engineering and supervisor offices that are incredibly convenient to order and install. All our panelized solutions are prefabricated in our modular facilities for fast and easy installation on-site.

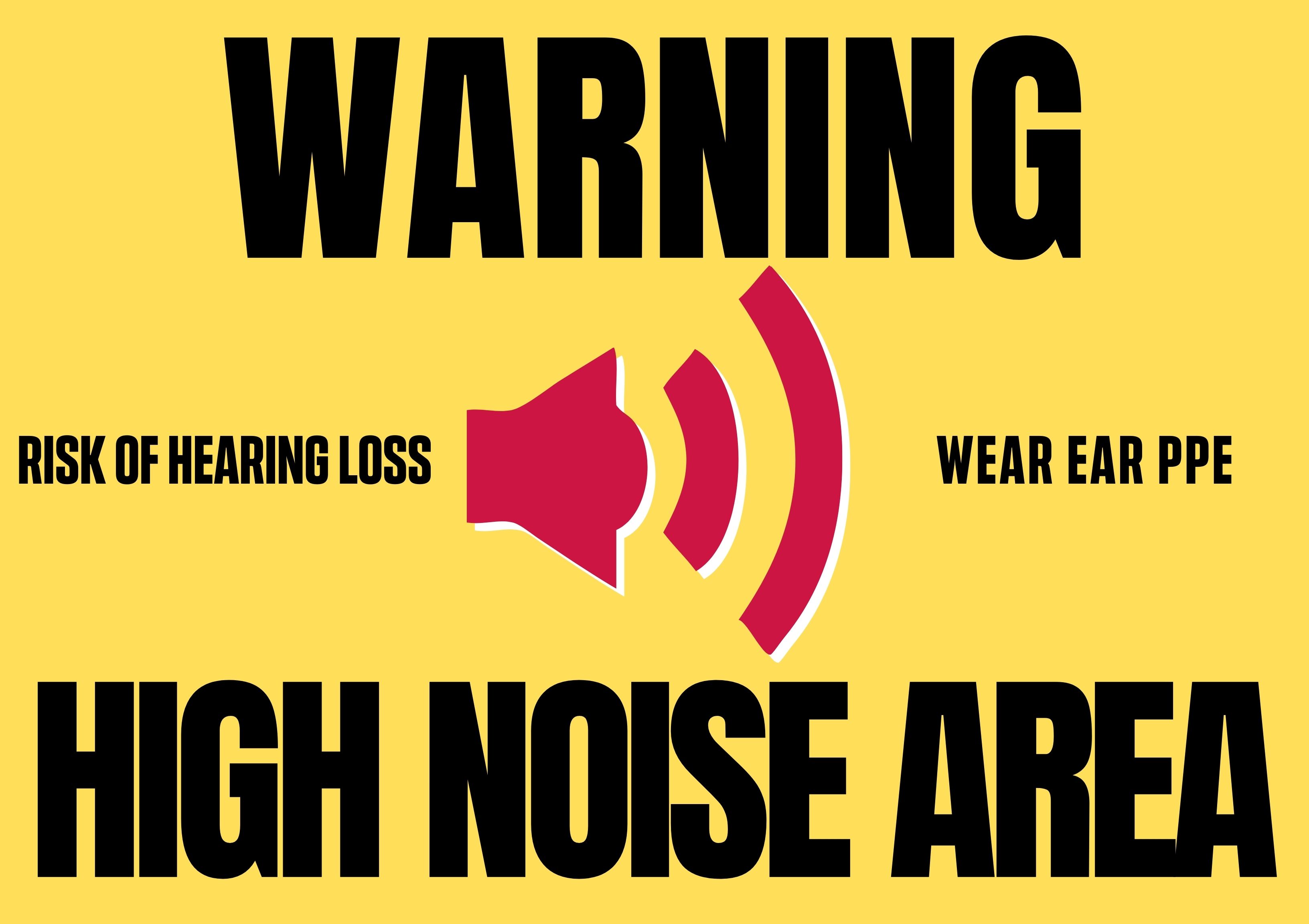

Mitigating Hazards Administratively

If noise cannot be controlled in a facility through these three methods, Administrative action may be needed to protect employees further. These are methods and procedures that businesses use to mitigate hearing damage through "signage, restricted access, and/or employee training." These actions help employees recognize and address potential noise hazards and instruct them to handle them properly. Further controls such as employee rotation programs can be used to reduce prolonged exposure to high volumns.

Addressing Noise Control with PPE

The final step in the Hierarchy is the use of PPE or Personal Protective Equipment. PPE is considered the least effective form of control because it relies on the proper execution by all employees in the face of a hazard. If anyone employee misuses or forgets their PPE, they can be fully susceptible to the risk if it has not already been mitigated through other channels.

However, this does not mean PPE is bad, just that other avenues should be explored first. For noise control, employers generally can offer two options: earplugs or earmuffs. Both options should be provided according to employee preference.

Ultimately, there are many different ways that businesses can reduce noise pollution in and around their facility. If noise cannot be mitigated through elimination or substitution, companies can come to Panel Built to explore the many different engineering control options available to them. Our modular wall design can form sound-dampening enclosures and office systems, perfect for quick, custom projects.

If you have any questions about how Panel Built can help you reduce the noise permeating through your facility, let us know! We are more than happy to design and quote the perfect equipment enclosure or sound dampening room for your facility. You can give us a call at 800.636.3873, send us an email to info@panelbuilt.com, or let us know in our LiveChat in the bottom-right of the page.