Modular Wiring: Your Electrical Made Easy

Electrical work can be the most important part of any new building project because electricity serves as one of the most essential parts of any building, whether it is in a home, office, school, or manufacturing facility. Because of this, proven, quality work must be done to ensure a safe, habitable environment and to prevent costly repairs. However, Panel Built’s modular wiring system creates a convenient, consistent, and dependable way to wire your new modular office systems. Utilizing standardized wiring components, this pre-wired, modular system can easily be snapped-together, creating a simplified way to connect the system.

What Is Modular Wiring?

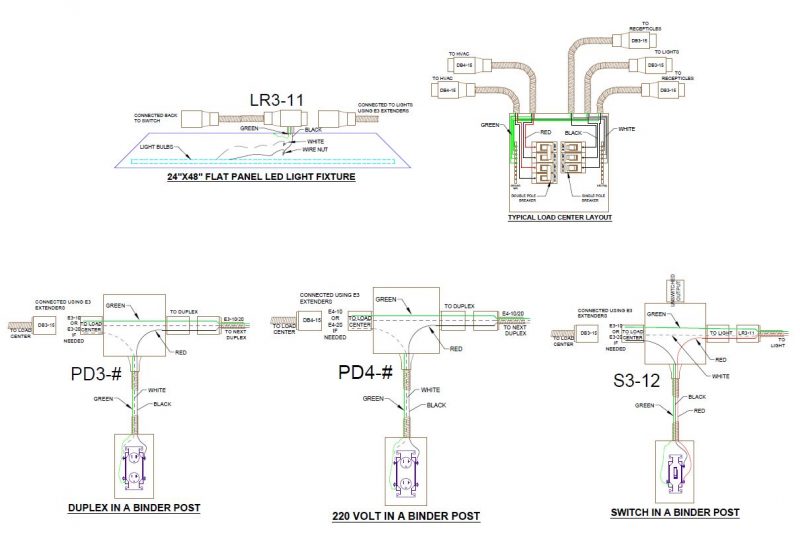

Modular Wiring is a simple electrical component system that allows for the pre-wiring of Panel Built’s building systems. In partnership with Power Built Modular Wiring, Panel Built streamlines the electrical process, significantly reducing on-site installation time by completing most of the wiring in our modular construction facilities. Unlike traditional wiring, modular wiring enables components to easily snap together, integrating seamlessly into Panel Built’s panelized wall assembly. Each wall panel connects via a binder post, which acts as a raceway for modular wiring whips. For office systems using this option, the binder post sections arrive at the job site pre-wired, eliminating an extra installation step.

What are the Benefits of Modular Wiring?

Overall Reduction in Labor Costs

One of the greatest benefits of utilizing modular wiring in your office system is the reduction you will see in labor costs associated with the project. Because the modular wiring system snaps together so cleanly and efficiently, the wiring installation required at the job site is taken care of incredibly quickly. And most importantly, the majority of the modular wiring process can be completed with a standard installation crew. The only portion of the install that requires an electrician is when the building is finally hooked up to a power source. With electricians requiring a much higher cost per hour, the labor cost of the overall project is greatly reduced.

Flexibility for the Future

One of the primary components of Panel Built’s building systems is the ability to be re-used, re-configured, and re-located. And when using modular wiring, your electrical can do the same. Because the Power Built systems utilize a series of snap-together cables and switch modules, the components can actually be reconfigured at a later date. With the semi-permanent nature of our modular building systems, modular wiring makes the process of uninstalling and reinstalling your building even easier.

Placing an Emphasis on Green Building

Like modular construction in general, modular wiring also promotes green building by reducing the amount of waste found at the project site. Additionally, the entire electrical assembly can be fully installed in a much more efficient manner than traditional construction, minimizing the amount of time and resources during the installation process. Additionally, if you decide to reconfigure your modular office system at a later date, the cables and switch modules can be easily disconnected and re-used in the next assembly.

Consistency & Quality That You Can Count On

With modular assembly, Panel Built uses a standardized electrical system deployed across hundreds of projects each year. That system is powered by Power Built—formerly PAC, a trusted name in modular wiring and now part of the Panel Built family. Combining decades of experience with a mission to deliver efficient, plug-and-play wiring systems, Power Built brings proven reliability to every build. Each binder-post system is pre-wired by one of our highly trained modular construction craftsmen, ensuring consistent quality, safety, and long-term performance. All modular wiring components used in our buildings are UL certified and tested for dependable results.

Time & Cost Savings With Modular Wiring

Traditional Wiring |

Modular Wiring |

|---|---|

| Main run from distribution board to distribution box (40ft) 85.30 Minutes | Main run from distribution board to distribution box (40ft) 51.00 Minutes |

| Install lighting control box (inc measure, mark, and fix) 9.00 Minutes | Install lighting control box (inc measure, mark, and fix) 5.00 Minutes |

| Connect lighting control box to distribution box (20ft) 52.50 Minutes | Connect lighting control box to distribution box (20ft) 27.00 Minutes |

| Install switch drop cable (5ft) 54.70 Minutes | Install switch drop cable(5ft) 8.00 Minutes |

| Run cable between 9 light fittings spaced at 5ft 209.90 Minutes | Run cable between 9 light fittings spaced at 5ft 48.00 Minutes |

|

|

| Cost Based on Average Electrician: $95.00 Per Hour | Cost Based on Average Factory Time: $35.00 Per Hour |

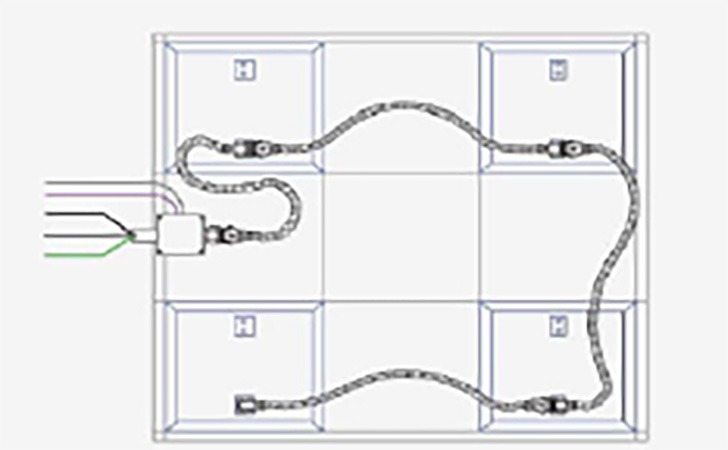

Modular Wiring Gallery

That is a quick run-down on how Panel Built's modular wiring helps ensure your modular office job is finished as quickly and conveniently as possible. After installing our Power Built modular wiring packages on thousands of different projects, we have the knowledge and expertise to ensure your building will be properly wired each and every time. If you have any questions about our modular wiring systems or would like to get a quote on a building with our modular wiring option, just give us a call at 800-636-3873 or send us an email at info@panelbuilt.com. We are always happy to answer any questions or concerns that you may have.