Wall Panel Configurations & Applications

Blog

Review a Selection of our Custom Wall Panel Offerings!

Standard Wall Panel Configurations

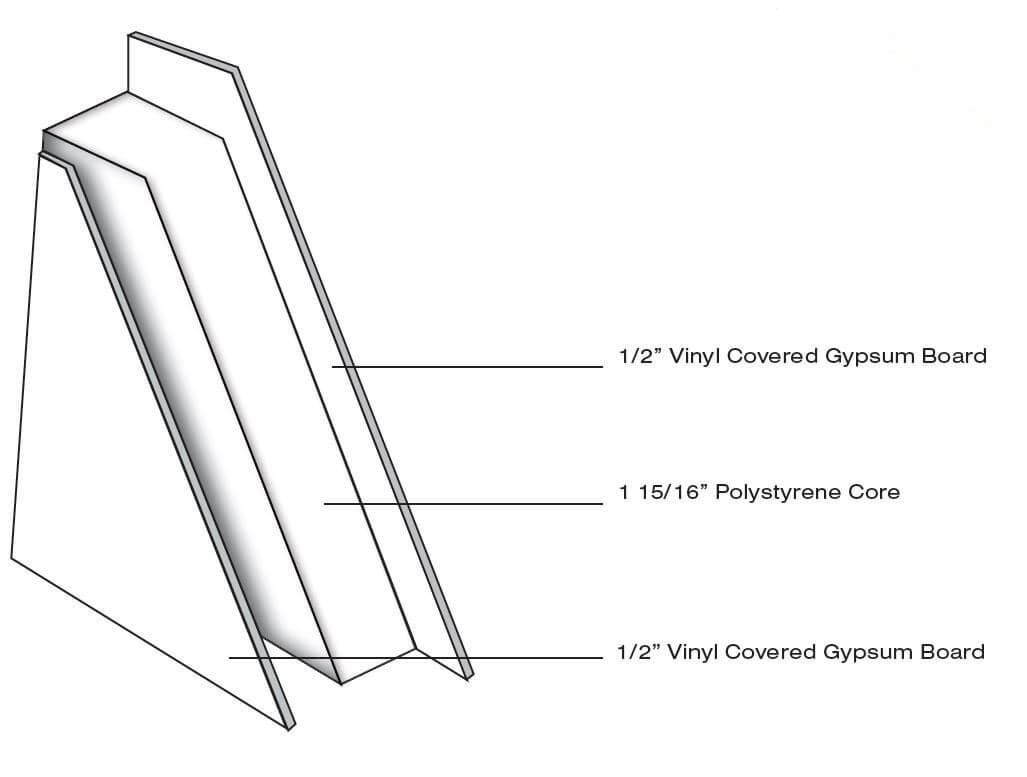

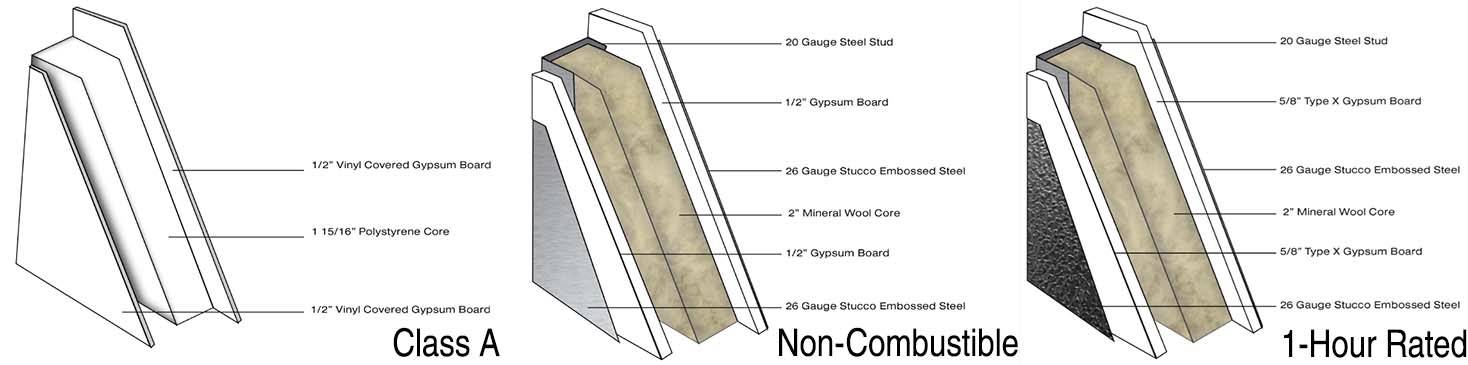

While Panel Built does make a wide range of custom sandwich panel configurations, we do have a few modular wall types that serve as our "Go-To" for many different applications. The first of these is our Vinyl-Covered Gypsum wall panel with a Polystyrene core. This panel (also referred to as a Gyp/Gyp panel) is considered our 'standard' wall panel system due to its ability to fit into a wide range of environments. Additionally, it is one of our most cost-effective wall panel solutions, making it a popular choice among customers. Our Gyp/Gyp panel fits into a wide range of environments because it provides good sound deadening and insulation with its polystyrene core. Plus, the vinyl covering provides additional durability while creating an easily cleaned wall surface. The panel also provides a Class A fire rating (lower flame spread) which can be required in certain environments.

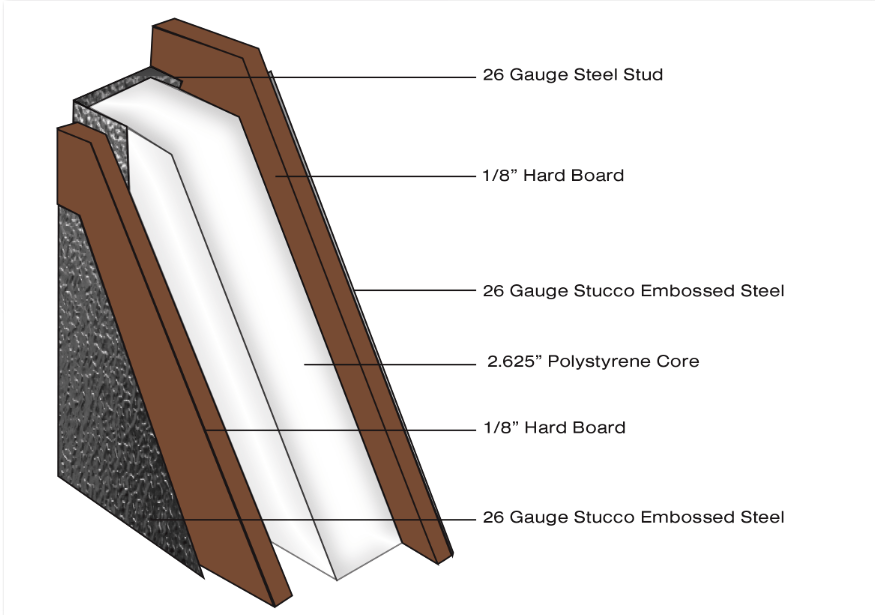

Our steel skinned wall panel (Steel/Steel or S/S) is another common wall panel type which is more likely to be found in our exterior modular buildings. This panel offers two 26 gauge steel skins sandwiching a polystyrene core (3" thick overall). and works best in exterior applications due to its increased impact resistance and great insulating properties. This panel will be frequently found in our modular guard booths and exterior equipment enclosures because the highly durable panels easily handle harsh environments and can be easily cleaned if in contact with dirt and grime.

While Panel Built does make a wide range of custom sandwich panel configurations, we do have a few modular wall types that serve as our "Go-To" for many different applications. The first of these is our Vinyl-Covered Gypsum wall panel with a Polystyrene core. This panel (also referred to as a Gyp/Gyp panel) is considered our 'standard' wall panel system due to its ability to fit into a wide range of environments. Additionally, it is one of our most cost-effective wall panel solutions, making it a popular choice among customers. Our Gyp/Gyp panel fits into a wide range of environments because it provides good sound deadening and insulation with its polystyrene core. Plus, the vinyl covering provides additional durability while creating an easily cleaned wall surface. The panel also provides a Class A fire rating (lower flame spread) which can be required in certain environments.

Our steel skinned wall panel (Steel/Steel or S/S) is another common wall panel type which is more likely to be found in our exterior modular buildings. This panel offers two 26 gauge steel skins sandwiching a polystyrene core (3" thick overall). and works best in exterior applications due to its increased impact resistance and great insulating properties. This panel will be frequently found in our modular guard booths and exterior equipment enclosures because the highly durable panels easily handle harsh environments and can be easily cleaned if in contact with dirt and grime.

Common Wall Panel Substrates

Adding substrates to common wall configurations (like Gyp/Gyp or S/S) is a great way to customize your building to best fit your facility's unique environment. In most cases, the job of the substrate is to strengthen certain properties of the wall panel that cannot be accomplished with the panel's outer facing alone. One of the most common substrates we use is a specialized sound-dampening board. This is a half-inch thick fiberboard that is laminated to the panel's core. The board offers a high quality, yet cost-effective way to absorb vibrations carried through the wall panel, reducing the sound transmission permitted through the panel. This substrate is often used in modular offices in heavy manufacturing environments, operator control booths, and in equipment enclosures which aim to reduce a machine's noise output.

Adding substrates to common wall configurations (like Gyp/Gyp or S/S) is a great way to customize your building to best fit your facility's unique environment. In most cases, the job of the substrate is to strengthen certain properties of the wall panel that cannot be accomplished with the panel's outer facing alone. One of the most common substrates we use is a specialized sound-dampening board. This is a half-inch thick fiberboard that is laminated to the panel's core. The board offers a high quality, yet cost-effective way to absorb vibrations carried through the wall panel, reducing the sound transmission permitted through the panel. This substrate is often used in modular offices in heavy manufacturing environments, operator control booths, and in equipment enclosures which aim to reduce a machine's noise output.

Another common substrate featured in Panel Built's Wall Panel Configuration is hardboard which can be used to strengthen our gypsum and steel wall panels. The addition of hardboard to our S/S panel creates our most durable wall panel, capable of withstanding even the harshest environments. In other cases, hardboard can be installed into Gyp/Gyp wall panels if that panel will have something mounted to it (cabinets, televisions, etc.) after the building is installed at the job site.

In some cases, the gypsum board itself can act as a substrate in a wall panel, specifically when utilizing a steel skin finish over the gypsum. This panel has a Steel-Gypsum/Gypsum-Steel configuration which grants the building the high durability of a steel panel while still achieving a Class A rating and low sound transmission of a gypsum panel.

Another common substrate featured in Panel Built's Wall Panel Configuration is hardboard which can be used to strengthen our gypsum and steel wall panels. The addition of hardboard to our S/S panel creates our most durable wall panel, capable of withstanding even the harshest environments. In other cases, hardboard can be installed into Gyp/Gyp wall panels if that panel will have something mounted to it (cabinets, televisions, etc.) after the building is installed at the job site.

In some cases, the gypsum board itself can act as a substrate in a wall panel, specifically when utilizing a steel skin finish over the gypsum. This panel has a Steel-Gypsum/Gypsum-Steel configuration which grants the building the high durability of a steel panel while still achieving a Class A rating and low sound transmission of a gypsum panel.

Wall Panel Cores

The final component of Panel Built's wall systems and perhaps the most important, are the panel cores which provide the majority of the insulative properties for the buildings. The primary core material that will be found in most of our wall panel configurations is polystyrene. Polystyrene is a very popular material in building projects as an affordable, lightweight, and water-resistant insulator. However, there are a couple of reasons why another wall panel core may be needed for your project.

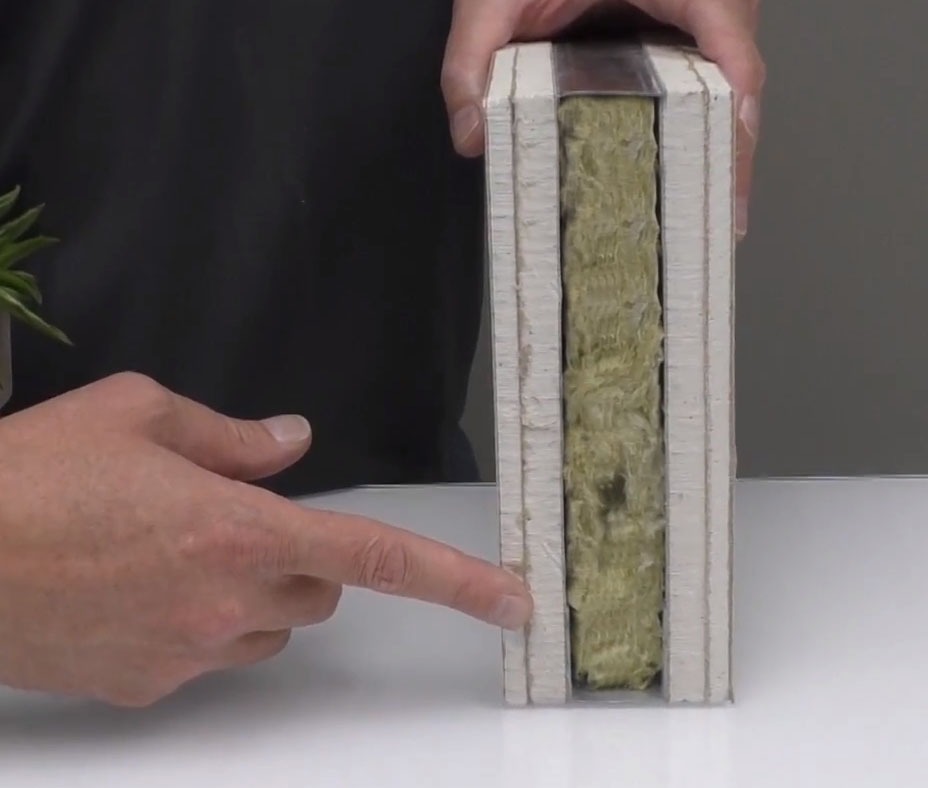

First, the project may require a more strict fire rating than the Class A rating that accompanies our standard Gyp/Gyp panel with a polystyrene core. In these cases, Panel Built has developed two specialty panels: a Non-Combustible rating and a One-Hour Fire Rating. Both of these wall systems utilize a special core material in order to achieve this higher fire resistance: mineral wool. In addition to high fire resistance, panels with mineral wool cores achieve great sound absorbing and thermal insulation.

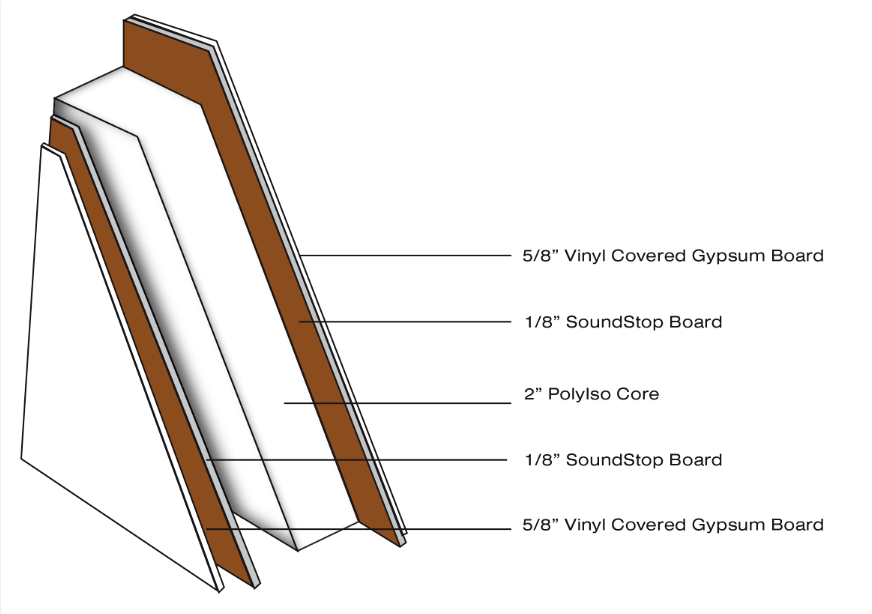

Second, the project may be found in a colder (or hotter) environment and may want to increase the insulative properties of their wall system to save money on heating and cooling in the long run. In this case, Panel Built will utilize polyisocyanurate thermal insulation. This core, also called Polyiso, has a very similar sound transmission rating; however, the core's R-value (insulation rating) of 17, compared to the R-value of 11 gained from polystyrene. This boosted insulation allows the building envelope to more easily retain heat, lowing the power to keep a stable temperature in the long run.

The final component of Panel Built's wall systems and perhaps the most important, are the panel cores which provide the majority of the insulative properties for the buildings. The primary core material that will be found in most of our wall panel configurations is polystyrene. Polystyrene is a very popular material in building projects as an affordable, lightweight, and water-resistant insulator. However, there are a couple of reasons why another wall panel core may be needed for your project.

First, the project may require a more strict fire rating than the Class A rating that accompanies our standard Gyp/Gyp panel with a polystyrene core. In these cases, Panel Built has developed two specialty panels: a Non-Combustible rating and a One-Hour Fire Rating. Both of these wall systems utilize a special core material in order to achieve this higher fire resistance: mineral wool. In addition to high fire resistance, panels with mineral wool cores achieve great sound absorbing and thermal insulation.

Second, the project may be found in a colder (or hotter) environment and may want to increase the insulative properties of their wall system to save money on heating and cooling in the long run. In this case, Panel Built will utilize polyisocyanurate thermal insulation. This core, also called Polyiso, has a very similar sound transmission rating; however, the core's R-value (insulation rating) of 17, compared to the R-value of 11 gained from polystyrene. This boosted insulation allows the building envelope to more easily retain heat, lowing the power to keep a stable temperature in the long run.

Panel Built, Inc. has developed this wide variety of wall panel configurations in order to best fit our customers' needs from project to project. Our mission is, "To Solve Our Customers' Space Needs with Excellence and Great Customer Service" and perfectly tailoring our product to meet your needs is a big part of that mission. If there's a particular panel facing, substrate, or core that you'd like to use in our wall system, let us know! We're always looking to grow and expand our offerings. You can reach us by phone over 800-636-3873, via email through info@Panelbuilt.com, or through our LiveChat in the bottom-right of the page.