Why Choose Modular for Your Facility's New Enclosure?

There are many reasons why a company may need to create an enclosure inside of their facility. The company may be expanding their production capabilities and installing a new piece of equipment which requires a highly controlled environment with which to operate. There may be existing equipment that gives off pollution in the form of heat, sound, or debris, in which an enclosure can separate this pollution from the rest of the facility. But whatever the reason may be, many manufacturing facilities will find their facility could benefit from an equipment enclosure or machine enclosure over the course of time.

However, there are a few different ways that companies can address this new need. We have found that many companies will actually try to address their new enclosure needs in-house, using their current employees spearhead a stick-built enclosure project.

This solution can be appealing to companies that are trying to find the most cost-effective solution possible to their enclosure project. Although, this avenue can end up being very troublesome for facilities in the long run and throughout the duration of the project. In many cases, these facilities may not have employees with experience working on construction projects such as these leading to many errors, longer project times, and sub-standard construction.

If the facility had instead elected to utilize modular construction on their enclosure project, they would have found a number of benefits to this unique construction type. Modular construction can offer advantages for facilities as far as project time, financially, long term flexibility, and overall project efficiency. And we will go over all of these benefits and advantages in this post.

Flexibility for the Future of Your Facility

Flexibility is one of the primary benefits modular construction provides for businesses looking to provide an enclosure to the manufacturing facility. Thanks to our panelized wall systems, Panel Built's modular enclosures create a semi-permanent wall system that can be un-installed, rearranged, or moved at any time. Just as the need for an enclosure can arise at any moment for a company, the need to move or expand the structure may occur later down the road.

With a stick-built enclosure, this flexibility does not exist. The stick-built structure might need to be completely torn down in order for these changes to occur, leading to a great deal of construction waste and little to no re-usable material.

However, with our modular wall system, the same wall panels used to create your initial enclosure can be repurposed if the layout needs to be changed in the future. If the facility needs to install more of the same equipment into the enclosure, the wall system can be expanded, Panel Built can supply additional wall panels in order to create a larger enclosure.

Quick& Efficient Enclosure Installation On-Site

As Panel Built's modular enclosures are prefabricated in one of our modular construction factories, the amount of time spent installing the building on-site is greatly reduced. As Panel Built is fabricating the building, the project site can begin prepping the location for the installation, allowing the site prep and manufacturing stages of the project to occur simultaneously. This is a stark contrast to stick-built construction where the enclosure cannot be started until the site has already been prepared for work to begin. With this more efficient project timeline, facilities can expect to have their new modular enclosure installed into their facility at a fraction of the time of stick-built.

Additionally, when the professional installation team is there to install the building, there's far less waste and disruption on-site due to the components being pre-cut and ready for install. The enclosure will be delivered to the project site in a packaged on a skid, with the components ready for installation.

Project Designed & Delivered by Experts with a Proven History of Quality

Companies looking to handle their enclosure needs in-house can sometimes be susceptible to errors in design and execution when trying to build their own equipment or machinery enclosure. Working with Panel Built's team of modular construction experts, your project will be in the hands of a trained professional at each and every phase of the project. Being in the industry for 25 years, Panel Built has designed, engineered, fabricated, and installed custom enclosures for facilities of all types, including industrial printing machines, CMMs, laser enclosures, paint booths, product testing, and more!

Panel Built and our system of dealers all across the United States have the experience required to deliver an enclosure solution that best fits your facility's and equipment's needs. Panel Built has an Engineering team solely dedicated to working on this type of in-plant structure. They know the right questions to ask to ensure your new building will be installed and function just as intended.

Custom Wall Panel Materials for Your Specific Needs

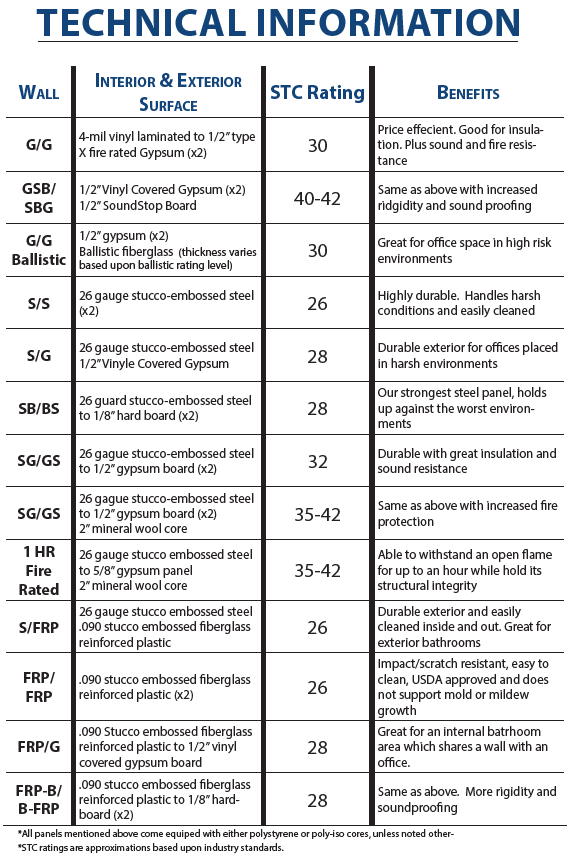

Each enclosure project will require specific attributes from the enclosure itself. Panel Built's line of panelized in-plant buildings can be fabricated from a variety of different wall panel types in order to meet the particular specifications for your project.

For example, a facility looking to enclose a loud machine would likely want an enclosure that offers extra sound dampening qualities. Panel Built can adapt our standard wall panel type, two-sided vinyl covered gypsum with a polystyrene core, to include an additional layer of sound deadening board. This additional layer goes a long ways to help minimize decibel levels in the rest of the facility.

Other instances of specialized wall panels include temperature control (higher density core for additional insulative properties), fire resistance (non-combustible and fire-rated wall assemblies), easy-clean environments (non-porous FRP wall facings), and more. If there's a particular attribute your enclosure needs, let us know and we will configure a wall panel to best address the issue.

One of the biggest advantages that modular enclosures offer is the assurance that your project is in the handles of a professional, expert team. In addition to being a quick and convenient space solution, Panel Built's buildings offer additional tax advantages over stick-built, allowing you to depreciate the new structure over a much shorter period of time (compared to nearly 40 years with traditional construction methods).

If you have any questions about Panel Built's modular enclosures or would like to get a quote on an enclosure of your own, let us know! We're more than happy to help with any questions or concerns that you may have. You can give us a call at 800.636.3873, send us over an email to info@panelbuilt.com, or let us know in our LiveChat feature in the bottom-right of the page. Our mission is, "To Solve Our Customers' Space Needs with Excellence and Great Customer Service," and that is exactly what we aim to do with each project we deliver and every quote we provide.