4 Areas of Focus For A Productive Warehouse

Investing In Your Workers

We wanted to start with an area that might be overlooked on most warehouse improvement lists. One essential part of any business is the people who run it. Investing time and money into your employees' training and overall skills helps ensure an efficient and smooth-running warehouse.

This training should be offered to employees of all types and includes a thorough onboarding that introduces your company culture and mindset. However, perhaps more important is the ongoing maintenance training of all employees. Warehouse training can range from basic ergonomic lifting techniques to understanding performance metrics. Therefore, it is essential to understand what training is needed for each department.

However, cross-training has become an ever-growing technique for warehouse managers trying to increase the flexibility of their workforce. By lessening "highly specialized" work, your workforce can operate more efficiently. Tasks can be completed by multiple workers rather than those specific few. Employees then can function like "utility players" in baseball, able to be plugged into a variety of positions and perform well.

Minimize The Movement In Your Facility

When determining the layout of your warehouse, a central goal should be to minimize the overall movement in your facility. Whether referring to the transportation of materials or people, time spent traveling within your warehouse adds to the cost of your operations. The longer it takes to move from one stage to another, the more resources are spent. With hundreds of employees and thousands of pieces of inventory, warehouses with a practical layout will significantly save on in-warehouse transportation time and costs.

Of course, the best way to reduce this wasted motion is to generate an excellent layout for your facility. For example, inventory picking processes should end closest to your packaging/shipping areas. Additionally, materials and equipment used most often in a process should be placed near their packaging/production space.

Communicating with Employees

Another critical focus should be listening to your employees. No one understands a company's day-to-day strengths and weaknesses better than those on the floor making things happen. Listening to them about different aspects of the warehouse and work processes is a helpful alternative perspective.

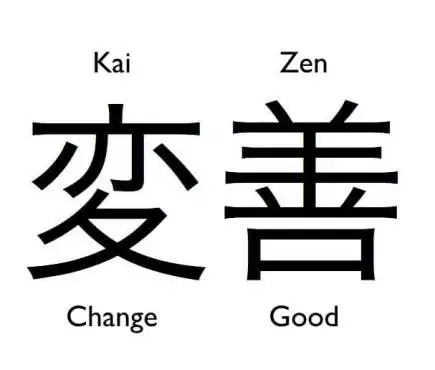

This communication is vital to Kaizen , the " continuous improvements " the " continuous improvements " that highly productive warehouses make. Because plant operators work hands-on with equipment and materials daily, they are more likely to notice small details that may have been overlooked. The core of the Kaizen ideology is to make minor enhancements to your system constantly. >Giving employees a platform to make recommendations and be recognized/rewarded positively aligns with your goals, promoting regular Kaizen submissions and improvements.

Optimizing Your Warehouse Space

Finally, the most common way to create a productive warehouse is to optimize the usable space inside your facility. One of the fastest ways to build an unproductive warehouse is to make it overcrowded. This disorder can lead to blocked traffic lanes or accidents in congested areas. With the high roofs of most warehouses, maximizing the use of your vertical space allows you to maximize your facility's potential.

Many warehouses already do this with their racking systems, sometimes expanding their racks up to the ceiling. However, this vertical space can also be used over other areas of your warehouse. Panel Built, Inc. manufactures custom warehouse mezzanines to fit these spaces in your facility. Additional office space, break rooms, storage space, and more can be installed to meet the unique space requirements of your facility. With their bolt-together design, the mezzanine platforms are prefabricated off-site and delivered for convenient assembly in your warehouse.

By elevating the space over your warehouse floor, you can nearly double the usable space in the area with minimal footprint in the area below.The steel assembly can also be designed to act as a catwalk, connecting two workstations. Catwalks can reduce the crossover of foot and forklift traffic, lowering the risk of an accident and preventing slowdowns in material transportation.

Overall, there are several ways to increase production in your warehouse. First, when companies invest in and gain feedback from their warehouse employees, they create a more flexible, efficient workforce that constantly aims to improve. With Kaizen, your warehouse continually makes minor improvements that accumulate to a significant increase in production over time. Finally, almost all warehouses have unused vertical space that can be utilized for extra storage and office space, allowing for a more precise and more organized space.

If you are interested in how Panel Built, Inc. can help you address your warehouse productivity needs through our space creating modular structures, just let us know! You can call us at 800.636.3873 , send us an email to info@panelbuilt.com , or let us know in our LiveChat in the bottom-right of the page. Our customer service driven team is more than happy to help with any questions or concerns.